Experimental Program

Following a literature review on the advantages and disadvantages of currently available mosaic backing methods, an alternative backing method was proposed based on two lime-based mortar layers. The first layer includes a thin, low-strength mortar with high lime content to provide chemical and physical compatibility with the mosaic tesserae. This layer also functions as an intervention layer to provide reversibility (i.e., to safely separate the mosaic from its support should this be necessary). The second layer is a stronger and thicker supporting layer with cost-effective panel reinforcement for structural purposes.

To assist in choosing mortar and reinforcement materials for testing, GCI conducted a survey of locally available materials in the countries of the MOSAIKON Initiative. Based on the survey results, four lime-based mortar types (lime, natural hydraulic lime [NHL], lime-pozzolan [LP] and lime-Portland cement [LC]) and three types of cost-effective panel reinforcements (paving [Geonets], floor- and light-shade plastic grids) were included in the research program.

The costs of the studied panels are in the range of $20–$30 per square meter while the cost of the European produced honeycomb aluminum panels available in the region is $450–$550 per square meter.

Mortar testing

The experimental program began with testing fifty-five mortar formulations to determine which combinations met the required mechanical and physical properties. GCI's aim is to make the backing as lightweight as possible while providing adequate flexural strength to support various sizes of mosaic pavements and to permit their safe transport.

Mid- and large-scale mockup testing

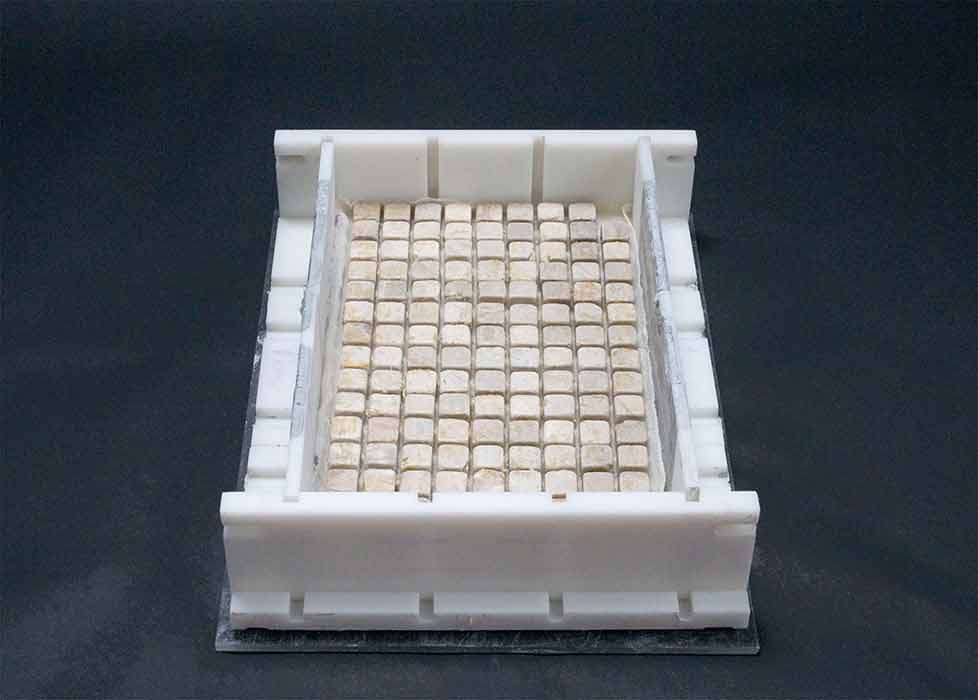

At present, research continues with testing of mid-scale mock-ups (16.5 cm x 25.5 cm) prepared using eleven selected mortar combinations, a variety of reinforcements, and commercially available travertine tesserae.

These mockups are being tested to determine:

(a) influence of reinforcing panels on load-bearing capacity, toughness, and deflection of the backing

(b optimal thickness of layers based on deflection

(c) bond between the intervention and supporting layers and between the reinforcement and supporting layers

(d) long-term durability of plastic reinforcement panels and overall backing

(e) final weight of backing systems

(f) effectiveness of the intervention layer (i.e. reversibility)

After completion of the mid-scale mockups, a limited number of large-scale mockups will be prepared and tested.